Industries

Launching AI is suitable for Electronics, Medical, Automobile, Food, Chemical fiber textile, Semiconductor, Machinery, Agriculture and other industries. It can help various industries realize AI empowerment of the real economy in an all-round way.

-

Mobile phone lens module appearance inspectionThe quality of the lens module is the key factor for an excellent camera effect of the mobile phone. The lens module has a high standard of appearance defect inspection requirements, including a total of 11 inspection items such as lens stains, poor lens coating, lens dirt, and reference surface scratches. Launching AI can realize the precise positioning of defect locations and complete the classification of defect types by training deep learning algorithm models.

Mobile phone lens module appearance inspectionThe quality of the lens module is the key factor for an excellent camera effect of the mobile phone. The lens module has a high standard of appearance defect inspection requirements, including a total of 11 inspection items such as lens stains, poor lens coating, lens dirt, and reference surface scratches. Launching AI can realize the precise positioning of defect locations and complete the classification of defect types by training deep learning algorithm models. -

Mobile phone body frame appearance inspectionDuring the production of the mobile phone body frame, defects such as burrs, silver threads, scratches, bruises, and spray leaks will occur. If these defects cannot be found in time, it will bring irreversible economic and material losses when the mobile phones enter the assembly process. Launching AI can realize the all-round appearance defect detection of the mobile phone frames by training the deep learning algorithm model and improve the quality of the products.

Mobile phone body frame appearance inspectionDuring the production of the mobile phone body frame, defects such as burrs, silver threads, scratches, bruises, and spray leaks will occur. If these defects cannot be found in time, it will bring irreversible economic and material losses when the mobile phones enter the assembly process. Launching AI can realize the all-round appearance defect detection of the mobile phone frames by training the deep learning algorithm model and improve the quality of the products. -

Ampoule appearance inspection- An ampoule is a small sealed glass vial which is used to contain and preserve a sample, usually a solid or liquid such as drugs for injection, vaccines, serum, etc. The main appearance defects are black spots, stones, cracks, dirt and damage on the ampoules. By training the deep learning algorithm model, Launching AI can complete the 0-360 degree full circle without dead angle inspection of the appearance of the ampoules. The accuracy can reach 0.1mm.

Ampoule appearance inspection- An ampoule is a small sealed glass vial which is used to contain and preserve a sample, usually a solid or liquid such as drugs for injection, vaccines, serum, etc. The main appearance defects are black spots, stones, cracks, dirt and damage on the ampoules. By training the deep learning algorithm model, Launching AI can complete the 0-360 degree full circle without dead angle inspection of the appearance of the ampoules. The accuracy can reach 0.1mm. -

Mask Appearance InspectionAffected by COVID-19, the supply of protective masks is in short supply, and the speed of manual inspection cannot keep up with the speed of production. By training the deep learning algorithm model, Launching AI can detect the dirt and foreign matters on the masks, the length and the solder joints of the ear straps, and the size of the mask and achieve fast rejection of defective products.

Mask Appearance InspectionAffected by COVID-19, the supply of protective masks is in short supply, and the speed of manual inspection cannot keep up with the speed of production. By training the deep learning algorithm model, Launching AI can detect the dirt and foreign matters on the masks, the length and the solder joints of the ear straps, and the size of the mask and achieve fast rejection of defective products. -

Bearing Appearance InspectionIn the process of bearing production and assembly, due to the influence of processing technology and some tiny foreign matters, defects will occur on the surface of the bearings. Common types of defects include cracks, black spots, rust, pits, scratches, missing covers, floating covers, and uneven chamfering. These defects not only affect the appearance of bearings, but also seriously affect the performance the products. Launching AI can realize the detection of bearing appearance defects by training the deep learning algorithm model, and automatically locate the defect area and defect type.

Bearing Appearance InspectionIn the process of bearing production and assembly, due to the influence of processing technology and some tiny foreign matters, defects will occur on the surface of the bearings. Common types of defects include cracks, black spots, rust, pits, scratches, missing covers, floating covers, and uneven chamfering. These defects not only affect the appearance of bearings, but also seriously affect the performance the products. Launching AI can realize the detection of bearing appearance defects by training the deep learning algorithm model, and automatically locate the defect area and defect type. -

Porcelain bottle inner wall quality inspectionOpaque porcelain bottles are often used to hold beverages and alcoholic beverages. Liquid filling has extremely high requirements on the quality of porcelain bottles, especially the cracks and cracks on the inner wall. The opacity makes the detection of the inner wall extremely difficult, and manual detection is extremely inefficient and prone to misjudgment. Launching AI can realize the precise judgment of inner wall defects by training the deep learning algorithm model, and can complete defect location and feature calculation in real time.

Porcelain bottle inner wall quality inspectionOpaque porcelain bottles are often used to hold beverages and alcoholic beverages. Liquid filling has extremely high requirements on the quality of porcelain bottles, especially the cracks and cracks on the inner wall. The opacity makes the detection of the inner wall extremely difficult, and manual detection is extremely inefficient and prone to misjudgment. Launching AI can realize the precise judgment of inner wall defects by training the deep learning algorithm model, and can complete defect location and feature calculation in real time. -

Capping, liquid level and spray coding inspection of PET bottlesPET plastic has the characteristics of light weight, high transparency, impact resistance, and not easy to break. It is often used to hold beverages and soda. Through training the deep learning algorithm model, Launching AI can realize the detection of missing caps, cap tilting, and cap sealing, and the detection of liquid level and spray codes.

Capping, liquid level and spray coding inspection of PET bottlesPET plastic has the characteristics of light weight, high transparency, impact resistance, and not easy to break. It is often used to hold beverages and soda. Through training the deep learning algorithm model, Launching AI can realize the detection of missing caps, cap tilting, and cap sealing, and the detection of liquid level and spray codes. -

DTY\FDY\POY surface inspectionChemical fiber is the raw material of cloth and clothing, and is widely used in daily life. The appearance of chemical fiber silk cakes has defects such as broken filament, over-thrown yarn, oil stains, package formation, etc. These defects will affect the quality of finished cloth and clothing. Launching AI can accurately judge the defect type and location by training the deep learning algorithm model, and complete the calculation of the defect area and size at the pixel level.

DTY\FDY\POY surface inspectionChemical fiber is the raw material of cloth and clothing, and is widely used in daily life. The appearance of chemical fiber silk cakes has defects such as broken filament, over-thrown yarn, oil stains, package formation, etc. These defects will affect the quality of finished cloth and clothing. Launching AI can accurately judge the defect type and location by training the deep learning algorithm model, and complete the calculation of the defect area and size at the pixel level. -

Viscose rayon surface inspectionViscose fiber, with a furry and fluffy feel, is suitable for making suits, blankets and brocade. Due to its high surface gloss and smooth feel, the price of materials made of viscose fiber is usually higher. There are defects such as broken filament, joints, oil stain, and color. Launching AI can achieve defect classification and judge the severity of defects by training deep learning algorithm models.

Viscose rayon surface inspectionViscose fiber, with a furry and fluffy feel, is suitable for making suits, blankets and brocade. Due to its high surface gloss and smooth feel, the price of materials made of viscose fiber is usually higher. There are defects such as broken filament, joints, oil stain, and color. Launching AI can achieve defect classification and judge the severity of defects by training deep learning algorithm models. -

Paper tube appearance testingThe paper tube is used to wrap the chemical fiber and viscose fiber, and the appearance quality of its surface has strict requirements. The defects such as stains, scratches and other defects of the paper skin on the paper tube, will broke or pollute the fiber shreds to hinder cloth textiles and dyeing. By training deep learning algorithm models, Launching AI can complete the 0-360 degree full circle without dead angle inspection of the paper tubes, and identify and position more than 20 different defects.

Paper tube appearance testingThe paper tube is used to wrap the chemical fiber and viscose fiber, and the appearance quality of its surface has strict requirements. The defects such as stains, scratches and other defects of the paper skin on the paper tube, will broke or pollute the fiber shreds to hinder cloth textiles and dyeing. By training deep learning algorithm models, Launching AI can complete the 0-360 degree full circle without dead angle inspection of the paper tubes, and identify and position more than 20 different defects. -

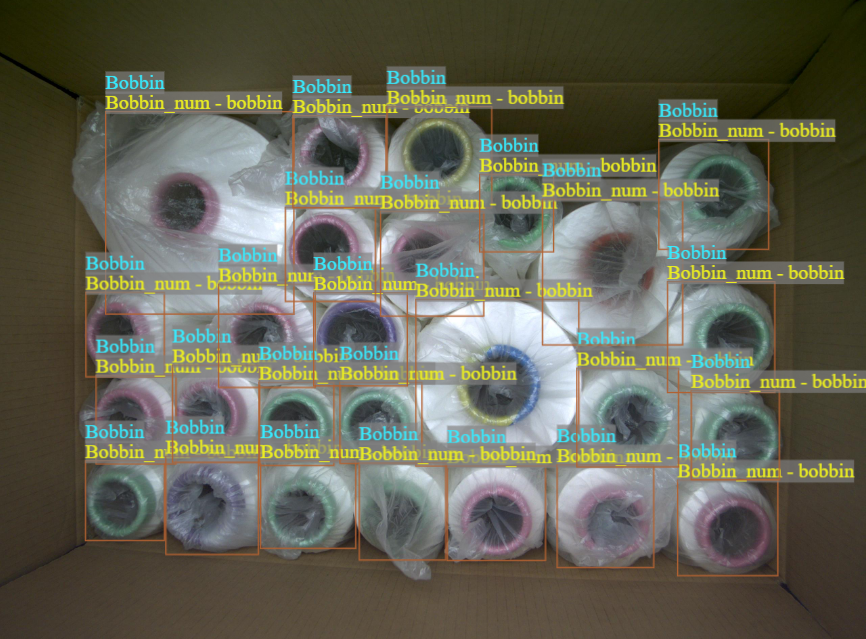

DTY Spindles countWhen Chemical Fiber and Viscose Fiber enters the package stage, the factory needs to count the number of silk spindles in the box. Launching AI can achieve the function of counting silk spindles through training deep learning algorithm models.

DTY Spindles countWhen Chemical Fiber and Viscose Fiber enters the package stage, the factory needs to count the number of silk spindles in the box. Launching AI can achieve the function of counting silk spindles through training deep learning algorithm models. -

Spinneret and spinneret hole inspectionThe spinneret is used to transform the adhesive high-polymer melting or solution to the fine stream with a specific cross-section through micropores, and to form a silk strip through the air or solidified bath. The size and quantity of the micropore above the spinneret will affect the specifications and the quality of the wire strips. Launching AI can calculate the number of micropores and the area of micropores by training deep learning algorithm models to achieve automated detection of spinneret.

Spinneret and spinneret hole inspectionThe spinneret is used to transform the adhesive high-polymer melting or solution to the fine stream with a specific cross-section through micropores, and to form a silk strip through the air or solidified bath. The size and quantity of the micropore above the spinneret will affect the specifications and the quality of the wire strips. Launching AI can calculate the number of micropores and the area of micropores by training deep learning algorithm models to achieve automated detection of spinneret.